I have been meaning to build this since the big remodel. You know the one. The back door that opens into a mess of coats and shoes and good intentions. This is my attempt to fix that.

Table of contents

Open Table of contents

The Problem I Kept Ignoring

After the remodel, this area opposite the back door became the dumping ground. Old open makeshift shelving full of book overflow, dog paraphernalia, cleaning supplies, and other junk needing a home. All framed by a hole with temporary baseboards tacked in place. I kept thinking, “I’ll build something for that.” Months went by. Then months turned to years.

The goal was simple: shelves that look like they are meant to be there. My wife added the requirement for hanging coats, which made complete sense after I resisted and then thought about it. The basement has a clean modern aesthetic, so I figured this should look minimal, painted in Benjamin Moore Pure White like the rest of the trim work and, most of all, be a great way to get myself back into cabinetry building.

The Design Tool I Finally Learned

Fusion 360 had been sitting on my hard drive for ages, quietly judging me. I’d dug up Bob Clagett’s “Fusion 360 For Makers” course I’d started years ago and found that Bob and team have completely revamped it. Check it out because it is fantastic.

The example project used in that course was perfect for a shelving built-in. Most of it stuck. Not all of it. But enough to model the cabinet without swearing too much.

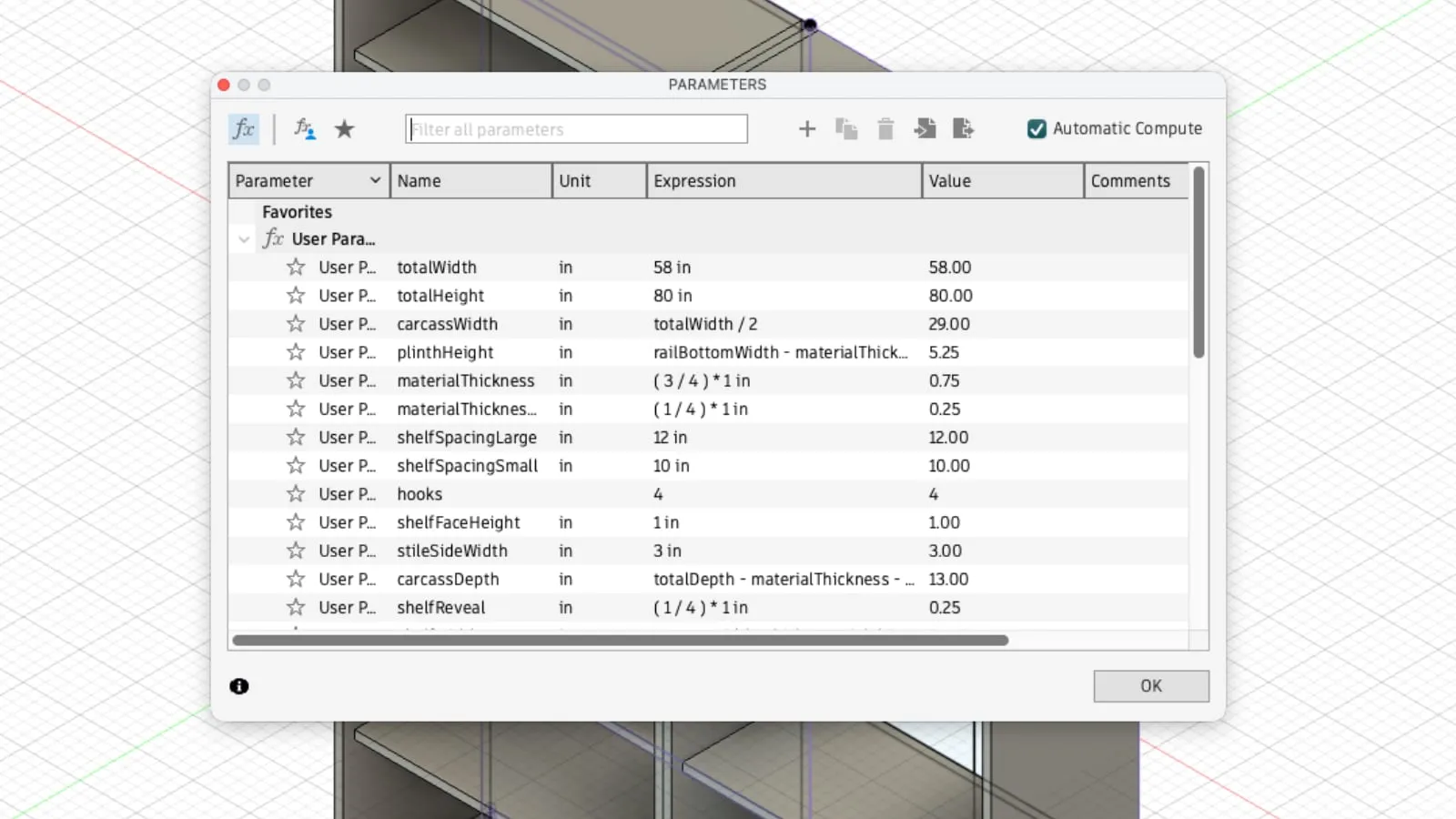

The parametric workflow was the revelation. The idea that the model isn’t just lines and shapes but, done correctly, a set of intentional dimensions you can revise later. I didn’t appreciate how useful that would be until I had to change the overall sizing midstream.

The Parametric Saves (And The Tweaks)

I’d made sure the inside dimensions of the void I was to fill were correct but, of course, I messed that up. Because I’d faithfully followed along with Bob, I had all the dimensions set up as variables in my model. Like magic, I could change what I needed and watch the whole model update. Game changer!

It was a snap to iterate on the shelf spacing based on the number of shelves I wanted and the minimum heights of large and small books. It’s like global variables in code; change in one place and view the effect everywhere. All without the sweat of fractional mathematics that comes with Imperial units.

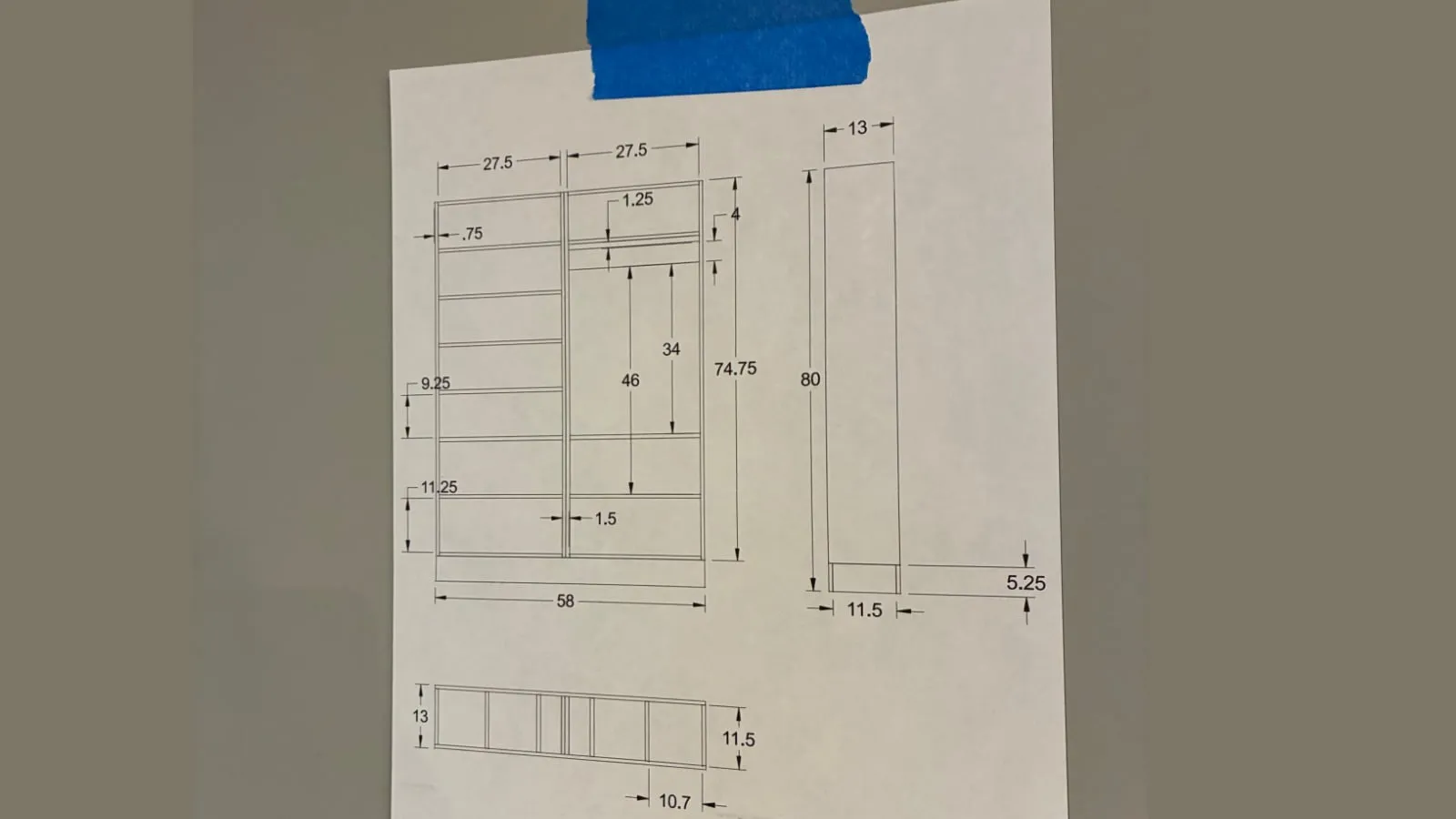

That said, I still ended up with a hand-drawn cut plan because the software doesn’t magically understand how I want to break down plywood. More on that later.

Cutting Plans: Fusion Gave Me Dimensions, Not A Cut List

I really like how Fusion can generate a dimensional plan with clean measurements that automatically adapt to any iterations. Way more readable than my usual scrawl. I still had to sketch out a cut plan by hand to give the lumberyard.

I must be missing a Fusion feature or some plugin that would help with generating the best use of stock material. If I find it, future me will be very happy.

Materials: Lumberyard Over Big-Box

I went to a local lumberyard instead of Home Depot. For a long time, I’d been told that was the thing to do, but it always felt a bit intimidating to turn up at a place like that. It was a better experience on every front: better material, better advice, and NOT spending hours shuffling through shoddy stock to find something worth the price.

I don’t know if it was cheaper, but I left with exactly what I needed, good quality stock, cut precisely to my specification, and it all fitted into the car. Brilliant!

The Toe-Kick Shortcut

I took a shortcut on the toe-kick. My DIY shop cabinetry uses the conventional notched side panels to accept a toe-kick but given this built-in didn’t have much depth, I wanted less of a reveal. I also didn’t want an eight inch high toe-kick to match the baseboard we have around the house. I ended up capping the baseboard at the edge of the built-in and putting everything on a 4 inch high plinth - the same height as the kitchen cabinets close by.

It sounds lazy because it was. But it made levelling the tall carcasses so much easier during their installation. They were plumb and horizontally aligned. The transition between baseboard and toe-kick is clean. The simple baseboard cap detail also matches the door opening opposite.

Scribing: I Tried, I Failed (Mostly)

In our previous house, I built a larger built-in and was proud of how the scribing turned out - the top rail of the face frame neatly snugged up against the wavy lines of our plastered ceiling.

This time? Meh. Not so much. I was careful to make the scribe line but my jigsaw cutting wasn’t great. I couldn’t find my compass, so I improvised with an eight inch spacer block taped to a pencil to make the marking on the rails and stiles. It’s not a disaster, but it has that “someone tried” look. The lesson: I need more practice, and probably a better method for transferring those wall irregularities.

The face frame joints were not that snug either. I need a better way to make those measurements and probably use biscuits, dowels, even pocket screws to flush those joints. The problem is, I like to do all stiles and rails in place using finish nails and glue because I’m not so confident my shop-built face frame will just fit into place.

Painting

This is the part I don’t look forward to. Well, that and sanding. The lumberyard gave me paint-grade plywood but I still need to learn how to apply paint so the grain doesn’t stand up. I’m assuming it’s better to fully brush with several coats of thinned paint instead of rolling the large areas with paint right out of the can. Still learning.

I don’t cut corners with caulking (aka “painter’s friend”) because it will show after you’ve put the final coat on. Lazy!

Closing Thought

I built the thing. It looks good from five feet away. And it works. The rest is just learning.

What this unlocked though, was the confidence to use Fusion for bigger cabinetry projects. Butler’s pantry. Kitchen makeover. Things I have been avoiding because I didn’t trust my planning. I’m not suddenly a pro, but I trust the process more now, which is almost the same thing… Nah. It’s not :)